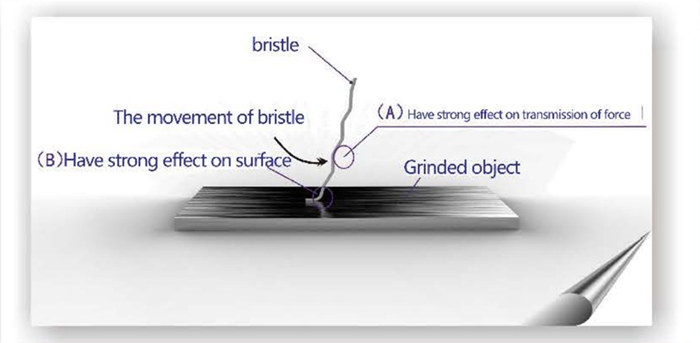

압연 공장에서는 세척, 연마, 디버링과 같은 금속 표면 처리에 브러시가 필수적입니다.

압연기용 브러시 선택에 영향을 미치는 세 가지 주요 요소는 필라멘트 재질, 브러시 구조 및 작업 조건입니다.

- 나일론 필라멘트

강력한 세척에는 경질 나일론이 적합합니다. 반대로, 미세 세척에는 연질 나일론이 필요합니다. 나일론 섬유의 장점은 내산성 및 내열성입니다. - 연마 필라멘트

연마 필라멘트는 나일론(PA6, PA612)에 연마재를 혼합한 것입니다. 직경은 0.46mm에서 1.78mm까지이며, 입자 크기는 60#에서 1000#까지입니다. 입자 크기가 클수록 연마 성능이 더욱 정밀해집니다.

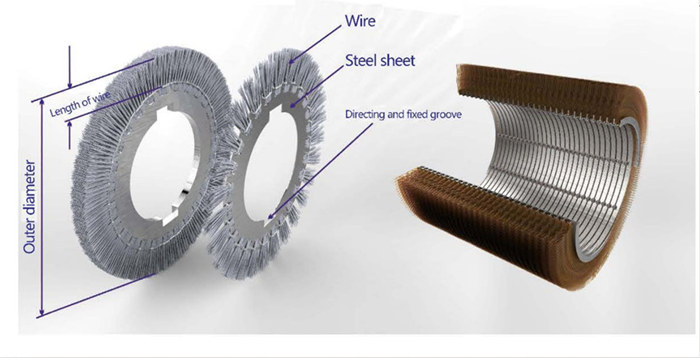

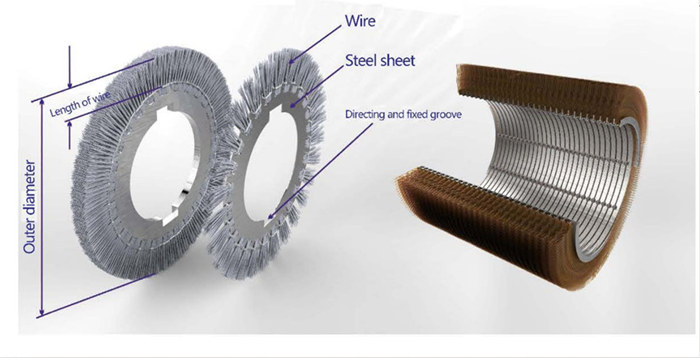

- 브러시 외경

외경이 클수록 다음과 같은 이점이 있습니다. 롤러 브러시 더 무거운 작업 부하를 처리하기 위해 설계되었습니다. 직경은 기계 크기와 회전 속도에 따라 맞춤 제작할 수 있습니다. - 필라멘트 작동 길이

이 매개변수는 브러시 수명과 기계 크기에 따라 달라집니다. - 필라멘트 추가

필라멘트 배열에는 카세트형과 나선형 두 가지 일반적인 유형이 있습니다. 따라서 브러시는 카세트 롤러 브러시와 나선형 롤러 브러시로 분류됩니다. 일부 응용 분야에서는 철사솔에 꼬여 있는 이러한 구조는 더욱 강력한 표면 처리와 내구성을 위해서도 사용됩니다.

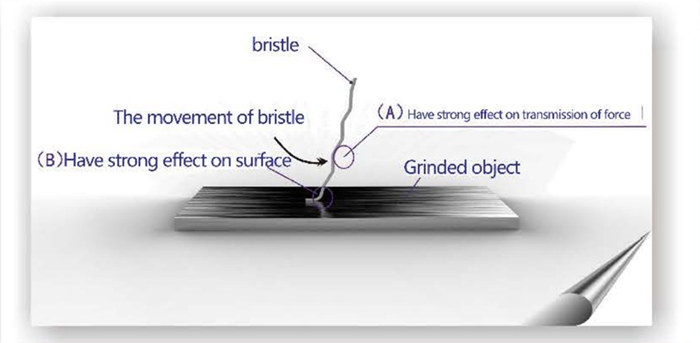

- 회전 속도(rpm)

회전 속도를 설정할 때는 세척 성능과 광택 성능을 최대한 활용해야 합니다. - 압력(A)

- 브러시에 뿌리는 스프레이

브러시가 금속 표면에 닿으면 온도가 계속 상승합니다. 스프레이를 사용하면 온도를 낮출 수 있습니다. 올바른 방향으로 스프레이를 분사하면 먼지를 제거하고 세척 성능을 향상시킬 수 있습니다. 스프레이를 사용하지 않으면 압연기용 브러시의 수명이 크게 단축됩니다.

더 자세한 내용을 알고 싶으시면 저희 웹사이트를 방문해 주세요.www.bajiebrush.com